16Inch 15 km/h Geared Hub Motor Kit With Canbus Controller

$159-$166

The 16-inch geared hub motor kit is suitable for ordinary heavy-duty agricultural vehicles or agricultural vehicles with encoders for four-wheel drive. It uses an electric brushless geared hub motor with an operating voltage of 48V, an output power of 500W, and a maximum speed of up to 15 km/h, providing stable and controllable performance in a variety of agricultural applications.

SPECIFICATIONS

| Model | LY16 |

| Motor Type | Electric Geared Hub Motor |

| Voltage(V) | 48 |

| Power(W) | 500 |

| Wheel size(Inch) | 16 |

| Speed(km/h) | 15 |

Product Display

The 16-inch wheel hub motor adopts a brushless DC (BLDC) motor design, which ensures minimal maintenance, longer service life and lower energy loss. The motor operates at 48V and has an output power of 500W, providing high torque performance, making it suitable for vehicles that require strong traction and consistent speed control.

The wheel hub motor with encoder is able to provide high-precision position and speed information, allowing the wheel hub to maintain high stability and accuracy during movement. This is especially important for scenarios that require high-precision positioning and motion control, such as automatic guided vehicles (AGVs) and robots.

The motor is ideal for four-wheel drive agricultural vehicles, agricultural robots and other heavy equipment that require precise motion control.

Product Feature

Hub Design

The motor uses an electric brushless gear hub design, which is smooth and low maintenance, minimizing energy loss and ensuring smooth operation even under heavy loads.

Wider range of use. Being able to control the speed of the motor, the brushless gear hub motor is suitable for more applications.

Longer service life and higher safety performance. Brushed motors require direct contact between the brushes and the commutator, while brushless motors have no friction between the brushes and the commutator, so there is no damage due to wear and tear, and the service life is longer than ordinary brushed motors.

Brushed motors are prone to sparking due to friction with the brushes, which may cause health and safety hazards in some cases.

Higher efficiency than brushed motors. The brushes in brushed motors reduce the efficiency of the motor, while brushless motors can be 85-90% efficient.

Quiet operation. Because there are no brushes, brushless motors are quieter than brushed motors and generate less electrical noise and interference, making them more suitable for industries such as medical, food or other noise-sensitive industries.

Configurations Available

The main parameters of this motor include rated voltage 48V, output power 500W, and speed 15 kilometers per hour. These specifications ensure a balance between power and energy efficiency, making it suitable for vehicles working in farmland or off-road environments.

The 16-inch wheel size provides excellent ground clearance and ensures better stability on uneven or rugged terrain.

The speed of 15 km/h is suitable for many agricultural tasks, enabling safe driving in situations where precise control is required, reducing potential damage to crops.

The 500-watt power is enough to drive a variety of agricultural and transportation equipment, ensuring sufficient power even under heavy load conditions.

Canbus Controller

A significant advantage of this motor kit is the integrated Canbus controller. The Canbus system enables efficient communication between vehicle components, thereby improving control, providing precise feedback and seamless integration with vehicle systems.

In addition, encoders can be added to this motor to improve the accuracy of speed and position control, making it an excellent choice for four-wheel drive agricultural vehicles that require advanced maneuverability.

Encoders are usually installed on the hub motor and integrated with the motor to quickly and accurately detect the operating status of the motor. According to the position and speed information fed back by the encoder, the operating status of the motor can be grasped in real time, and real-time control can be performed based on this information to achieve precise positioning and motion control. For example, when the AGV car is planning the path, the route should be adjusted according to the real-time position information of the motor to ensure that the car can reach the destination in time.

Product Applications

Heavy Duty Agricultural Vehicles

This hub motor can handle rugged terrain and is ideal for outdoor agricultural environments and challenging working conditions.

4WD Agricultural Vehicles

For use on in-line floor pans with encoders that enable fast response and precise actuation.

Electric Wheelbarrows

Suitable for small carts and unicycles, providing stable power for transportation tasks in industrial, agricultural and commercial environments

Related Products

Videos

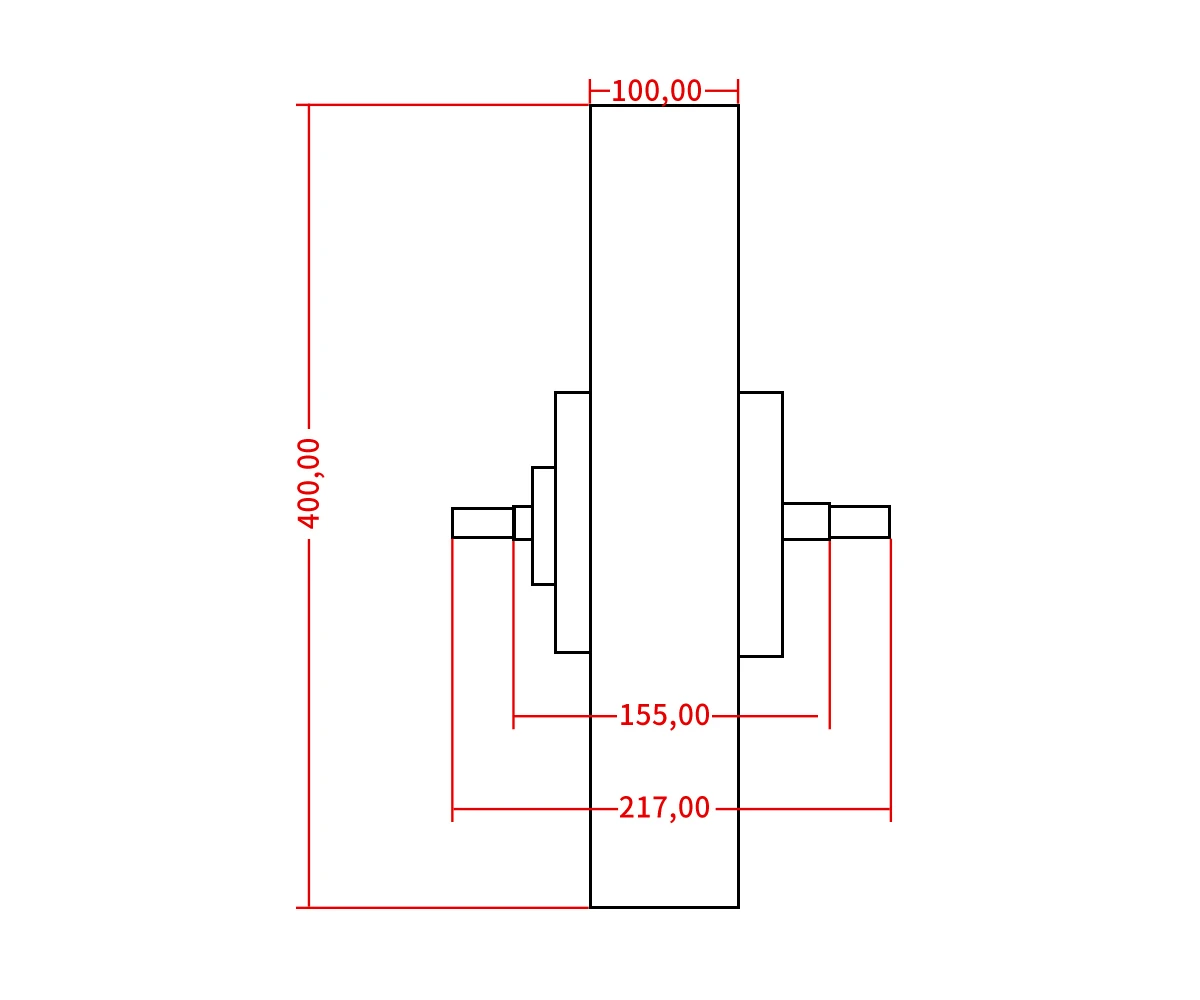

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00